ADC - Core Grades of Azodicarbonamide in Powder Form

Chemical: Azodicarbonamide | CAS No: 123-77-3 | Type: Exothermic Chemical Blowing Agents

Type: Exothermic Chemical Blowing Agents

Applications: Cross-linked PE/PP foams, PVC foams, artificial leather

Type: Exothermic Chemical Blowing Agents

Applications: PVC, PS, LDPE/HDPE, EVA, rubber compounds

Applications: EVA/LDPE foamed articles, cellular rubber products

Applications: Epoxy foams, rubber cloth laminates, sponge rubber

Applications: Crosslinked LDPE or PP foams with various cell structures

Applications: Rubber and polymer foaming applications

Applications: Coaxial cables, EPDM profiles, PVC footwear

Applications: High temperature processing of PS, PPO, HIPS, ABS

Applications: Activator for Azodicarbonamide at lower temperatures

Applications: EVA compression molding, extrusion and injection molding

Chemical: Azodicarbonamide | CAS No: 123-77-3 | Type: Exothermic Chemical Blowing Agents

| Grade | Particle Size (μm) | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|---|

| ADC-Z40 | 40 ± 5 | 230 ± 5 | 193 ± 3 | For low density cross-linked PE/PP foams |

| ADC-Z35 | 35 ± 2 | 230 ± 5 | 193 ± 5 | For low density cross-linked PE foams |

| ADC-Z25 | 22 ± 3 | 230 ± 5 | 200 ± 3 | For low density cross-linked PE foams |

| ADC-H18 | 18 ± 2 | 235 ± 5 | 200 ± 3 | For low density cross-linked PE foams |

| ADC-PNE-A13 | 12 ± 0.5 | 235 ± 5 | 200 ± 3 | For low density cross-linked PE and PVC foams |

| ADC-PNE-A12 | 11 ± 0.5 | 235 ± 5 | 200 ± 3 | For foamed articles based on PVC/PP/LDPE/ABS/rubbers. Most suitable in PVC calendar foams and ABS and PP extruded foams |

| ADC-PNE-A8 | 7 ± 0.5 | 235 ± 5 | 200 ± 3 | PVC leather cloth by spread coating |

| ADC-PNE-A5 | 5 ± 0.5 | 235 ± 5 | 200 ± 3 | PVC leather cloth by spread coating |

| ADC-PVC-A5 | 4.3 ± 0.5 | 235 ± 5 | 200 ± 3 | Artificial leather cloth and insulation products |

| ADC-PNE-H5 | 11 ± 1 | 230 ± 5 | 190 ± 2 | Rigid PVC foamed sheets and pipes |

| ADC-PVC-F5 | 5 ± 0.5 | 230 ± 5 | 190 ± 3 | Thicker artificial leather cloth (4 mm or more) |

| ADC-PVC-F3 | 4 ± 0.5 | 230 ± 5 | 190 ± 3 | Thicker artificial leather cloth (4 mm or more) |

| ADC-EVA-A9 | 8.3 ± 0.5 | 180 ± 5 | 190 ± 3 | For injection moulded cross-linked EVA footwear |

Chemical: Azodicarbonamide | CAS No: 123-77-3 | Type: Exothermic Chemical Blowing Agents

| Grade | Particle Size (μm) | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|---|

| ADC-4075 | 6 ± 0.5 | 230 ± 5 | 184 ± 2 | Production of plasticized & unplasticized PVC, PS, LDPE/HDPE, EVA, natural and synthetic rubber, silicone rubber, PP, ABS and nylon |

| ADC-F49 | 5 ± 0.5 | 230 ± 5 | 130 ± 2 | For whiter leather cloth by spread coating |

| ADC-1300 | - | - | 191 ± 3 | For PVC injection moulding as a density reducer |

| ADC-14D | - | - | 148 ± 2 | For cross-linked injection molded EVA footwear in combination with ADC-SA06 |

| ADC-SE | 5.5 ± 0.5 | 155 ± 5 | 142 ± 3 | One pack for leather cloth, ideal in chemically embossed foams |

| ADC-RE | - | - | 166 ± 3 | For production of PVC footwear, midsoles/insoles, EVA copolymer and foamed PVC leather cloth |

| ADC-21 | - | - | 160 ± 3 | For EPDM profiles with closed cell structure |

| ADC-AT | 5.5 ± 0.5 | 155 ± 5 | 160 ± 3 | For extruded white rigid PVC sheets |

| ADC-HT | 7 ± 0.5 | 170 ± 5 | 190 ± 3 | For whiter PVC shoe soles, beach sandals |

| ADC-EVA06 | 7 ± 0.5 | 220 ± 5 | 190 ± 3 | For EVA compounding (single system) |

| ADC-W | 5.5 ± 0.5 | - | 144 ± 3 | For whiter PVC shoe soles |

| ADC-HS1 | - | - | 182 ± 3 | For 2/3 layer LLDPE rotomoulded water tanks. Thicker and uniform sandwich layer |

| ADC-KSK | - | 228 ± 5 | 191 ± 2 | For production of light weight, cross-linked, extruded PE sheets in combinations with ADC-1500 PE |

| ADC-1500 PE | - | 195 ± 5 | 181 ± 3 | For production of light weight, cross-linked, extruded PE sheets in combinations with ADC-KSK |

| ADC-HP/LP | - | 190/198 ± 2 | 180/190 ± 5 | For extrusions LDPE/HDPE/PP films |

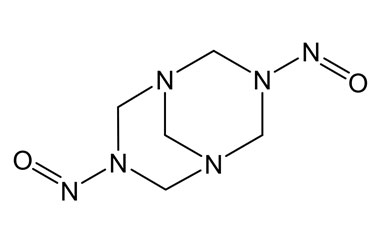

Chemical: Dinitrosopentamethylenetetramine | CAS No: 101-25-7

| Grade | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|

| DNPT | 120 ± 5 | 125 ± 2 | For thicker compression moulded EVA/LDPE foamed articles |

| DNPT (95/80/60/50%) | 220 ± 5 | 195 ± 3 | For cellular rubber products |

| EVY | 125 ± 5 | 120 ± 2 | For low temperature EVA/Dutch sheets |

Chemical: ExEn Series | CAS No: Mix CAS No.

| Grade | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|

| ExEn-27 | 110 ± 5 | 110 ± 5 | For epoxy foams, rubber cloth laminates, sponge rubber and slipper soles |

| ExEn-14 | - | 106 ± 3 | Non dusty version for epoxy foams, rubber cloth laminates, sponge rubber and slipper soles |

Chemical: Azodicarbonamide | CAS No: 123-77-3 | Type: Exothermic Chemical Blowing Agents

| Grade | Particle Size (μm) | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|---|

| CCXL-F | 11.5 - 15.5 | 220 ± 5 | 180 ± 5 | For chemical crosslinked LDPE or PP foams - Finer cell structure |

| CCXL-R | 11.5 - 15.5 | 230 ± 5 | 200 ± 5 | For chemical crosslinked LDPE or PP foams - Rough cell structure |

| CCXL-K | 11.5 - 15.5 | 230 ± 5 | 195 ± 5 | For chemical crosslinked LDPE or PP foams - General application |

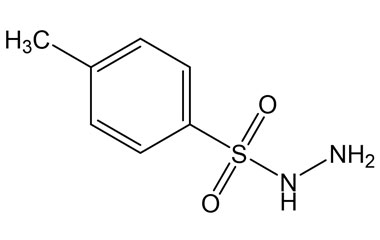

Chemical: p-Toulene Sulfonyl Hydrazinde | CAS No: 1576-35-8

| Grade | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|

| TSH | 110 ± 5 | 110 ± 5 | For epoxy foams, rubber cloth laminates, sponge rubber and slipper soles |

| TSH-W | - | 106 ± 3 | Non dusty version for epoxy foams, rubber cloth laminates, sponge rubber and slipper soles |

| TSH-MB | 80 ± 5 | 110 ± 5 | Master batch version in PE, PVC, EVA, EPDM as carrier |

Chemical: 4 4 '- Oxybis Benzenesulfonyl Hydrazide | CAS No: 80-51-3

| Grade | Particle Size (μm) | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|---|

| OBSH-I | 11 ± 2 | 120 ± 5 | 153 ± 2 | For coaxial cables, EPDM profiles, light color PVC footwear and microcellular rubbers |

| OBSH-II | 5 ± 2 | 120 ± 5 | 152 ± 2 | Synthetic/natural rubber, rotational moulding of LLDPE |

| OBSH-W | 8 ± 2 | 110 ± 5 | 152 ± 2 | Non dusty version for coaxial cables, EPDM profiles, light color PVC footwear and microcellular rubbers |

| BSH | - | - | - | For injection moulded PS, PPO, HIPS, ABS, PP, HDPE and rigid PVC |

| OBSH-MB | - | - | - | Master batch version in PE, PVC, EVA, EPDM as carrier |

Chemical: p-Toluene Sulfonyl Semicarbazide | CAS No: 10396-10-8

| Grade | Particle Size (μm) | Decomp. Temp (°C) | Gas Volume (ml/g) | Applications |

|---|---|---|---|---|

| TSSC | 5 ± 2 | 135 ± 5 | 225 ± 3 | For injection moulded PS, PPO, HIPS, ABS, PP, HDPE and rigid PVC |

| TSSC-W | 5 ± 2 | 128 ± 5 | 222 ± 2 | Non dusty version for injection moulded PS, PPO, HIPS, ABS, PP, HDPE and rigid PVC |

| BSSC | 5 ± 2 | 145 ± 5 | 215 ± 2 | For injection moulded PS, PPO, HIPS, ABS, PP, HDPE and rigid PVC |

| BSSC-W | 5 ± 2 | 138 ± 5 | 210 ± 2 | Non dusty version for injection moulded PS, PPO, HIPS, ABS, PP, HDPE and rigid PVC |

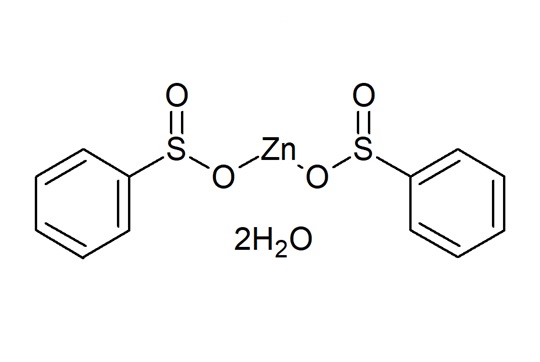

Chemical: Zinc Benzene Sulfinate | CAS No: 24308-84-7

| Grade | Gas Volume (ml/g) | Applications |

|---|---|---|

| ZBS | 218 ± 3 | Activator for Azodicarbonamide for helping production of foamed articles at lower temperature |

Base: Modified Azodicarbonamide in EVA Resin as Carrier | CAS No: 123-77-3

| Grade | EVA Content (%) | Decomp. Temp (°C) | Gas Volume (ml/g) | MI (g/10min) | Appearance |

|---|---|---|---|---|---|

| MBX 47 D | 55 | 80 ± 5 | 145 ± 5 | 21 | Pale Yellow Pellet |

| MBX 47 D2 | 55 | 85 ± 5 | 145 ± 5 | 21 | Pale Yellow Pellet |

| MBX 47 DH | 55 | 90 ± 5 | 165 ± 5 | 21 | Pale Yellow Pellet |

| MBX 30 D5 | 55 | 100 ± 5 | 155 ± 5 | 22 | Pale Yellow Pellet |

| MBX 60 DT | 50 | 130 ± 5 | 200 ± 5 | 21 | Yellow Pellet |